As an example, in 2020, the FDA announced that some medications had been contaminated which has a ‘probable human carcinogen called NMDA.’ This occurred since there was a lack of controls to take care of an aseptic natural environment.

From the dynamic realm of pharmaceutical manufacturing, liquid bottle filling machines stand given that the vanguards of performance and precision. These reducing-edge automatic units have sparked a revolution in the packaging of pharmaceutical liquids, propelling productiveness when upholding uncompromising high quality Command.

By adhering to stringent hygiene specifications, these equipment safeguard solution integrity and make sure that drugs are safe to be used.

The importance of liquid bottle filling equipment lies in their capacity to streamline the intricate process of filling liquid drugs into bottles with unparalleled efficiency. Classic manual filling techniques were prone to human errors, bringing about inconsistent dosages, contamination threats, and amplified generation time.

A whole, on-likely upkeep application should be produced and implemented. Matters being exclusively protected in the upkeep system really should include things like These products detailed underneath Tools Qualification. Also, examination and replacement of elastomeric seals, and also the ailment of molds, dies and pins must be website monitored. This system applies to all supporting machines and devices at the same time.

BevSource may help you find the proper facility and set a approach collectively for your personal financial investment decision.

Renaissance has a long time of knowledge in improvement and filling of aseptic products at the very best amount for that US and world-wide marketplaces. Situated over the east Coastline of The us, our point out-of-the-art amenities and gear can assistance a broad choice of sterile and/or environmentally managed products and solutions.

Aseptic processing is fairly hard because it needs elaborate engineering of operations to prevent the contamination of solutions. Enable’s discover these issues more.

The Biosealer® TC simplifies warmth-sealing with a user-friendly moveable design, highly secure thermal seals in addition to a new amount of versatility. Begin to see the movie to learn how the Biosealer® TC improves thermoplastic tube-sealing.

The assistance furnished by all approach owners and supervisors is greatly appreciated for the dear feed-back and brainstorming classes furnished by in defining hazards during the cleanroom entry and exit procedures, glass bottle washing equipment operation, and glass filling process.

With the inventive dip tube suggestion for max fluid removal on the QUICKSEAL® aseptic disconnection, Mycap® is surely an adaptable Alternative for almost any software.

Absence of web site supervision. No or inadequate Regulate on readers getting into cleanrooms. No posters read more stating photos are prohibited. Not enough employees consciousness

Sterile filling and aseptic filling go through various microbial avoidance procedures. The sterile fill/end method is about sterilizing the drug formulations, containers, and manufacturing atmosphere to get rid of microorganisms.

A comprehensive portfolio of normal and customized tube sets for transfer, distribution or filling of in-course of action fluids.

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Michael Fishman Then & Now!

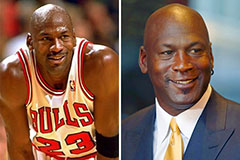

Michael Fishman Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!